Farmer's Diary

Mushroom Experts

Grow Bags

Getting to Know Grow Bags

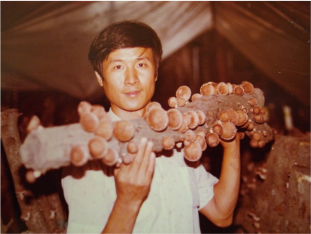

In the early days, shiitake mushroom cultivation relied solely on traditional methods using hardwood logs. Due to the high cost, only a few families could afford it. At that time, even with a bag of money, one might not be able to exchange it for a pound of shiitake mushrooms. In 1981, Taiwan invented the grow bag cultivation technique, with Mr. Zheng Wen-Qian being one of the inventors of the grow bag. This innovation marked a major milestone in the development of edible mushroom cultivation in Taiwan. Today, thanks to this technological breakthrough, shiitake mushrooms have become a common dish, easily accessible for every family to enjoy.

SpaceBag Production Processes

1. Wood Chip Piling

The main material for space bags is wood chips, usually from Taiwan's broadleaf trees, like acacia and oak. The wood chips are stored outdoors, turned, watered, and sun-dried for about a month to soften and ferment before use. Farms work with manufacturers to collect tree trimmings and scrap wood, which are shredded for space bag production. Recently, coffee grounds, peanut shells, and corn cobs have been added to replace some of the wood chips, making the process more eco-friendly.

2. Mixing Ingredients

After fermentation, the wood chips are mixed with rice bran, wheat bran, and calcium carbonate. The wood chips provide the base for mushroom growth, while the rice and wheat bran offer nutrients. Calcium carbonate adjusts the pH, and water is added. The mixture is then blended to create an ideal growing medium for mushrooms.

3. Packaging and Pressing

The mixture passes through a vibrating sieve to remove larger chunks and debris, preventing the plastic bags from being punctured and reducing contamination risks. The mixture is then sent to a semi-automatic packing machine, which fills the plastic bags. Workers insert a plastic ring at the opening for inoculation and seal it with cotton to keep it breathable. The semi-automatic machine can produce around 32 bags per minute, with a daily capacity of 24,000 bags.

4. High-Temperature Sterilization

The space bags can't be inoculated immediately because they may contain harmful microorganisms. Therefore, they are sterilized with steam at 98°C and high pressure for 9 hours to eliminate contaminants.

5. Natural Cooling

After sterilization, the space bags are too hot for inoculation. They need to cool down to about 30°C before inoculation can begin.

6. Inoculation

After the space bags have cooled, they are transferred to a clean room for inoculation. First, the cotton is removed, and the prepared spawn is crushed and poured into the space bag. Then, the cotton is replaced, completing the inoculation. The inoculation process must be carried out in a dust-free, sterile environment to ensure the quality of the space bags.

7. Mushroom Cultivation

The inoculated space bags are left to rest for a period to allow the mycelium to mature. Once the mycelium is ready, the bags are moved to the mushroom house for cultivation. The temperature, humidity, and light conditions are adjusted according to the needs of the specific type of mushroom being cultivated.